Infarmed Report

Summary

The Infarmed Report is a system-generated compliance record based on the Requirements from the document “Instruções de preenchimento do reporte trimestral da Canábis” published in July 2025 by Infarmed, that:

Ensures batch-level traceability

Supports accurate inventory control

Facilitates regulatory audits and reporting

End users are responsible for reviewing, validating, and confirming accuracy.

To create the report, follow the instructions found here: Creating a report

Make sure to always select first of January for the Start date of the report to include all entries through the year.

Data Definitions

Company Info

This table displayes the following company related information:

Company Name

License Number

Address of cultivation premises

Municipality

District

Authorized cultivation area

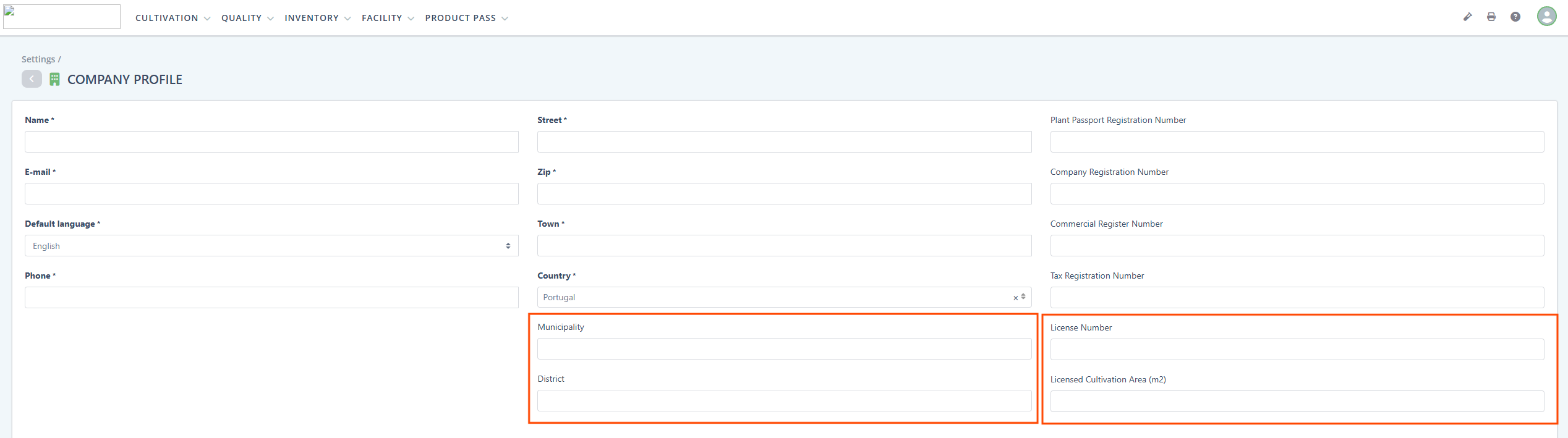

To add this information in Cannavigia follow these steps:

Navigate to Profile > Company Profile

Enter the marked fields

Click Save

Table 1: Seeds and Clones

This report includes data related to seeds and clones used in cannabis cultivation and is automatically generated from the Cannavigia system.

It provides a clear overview of all plant batches and article batches relevant to seed and clone activity within the selected reporting period.

The following data are included:

Plant Batches

Only batches created through the action “Take Cuttings.”

The Immature Actual Start Date must fall within the selected reporting month.

Mother plants and archived batches are excluded.

Article Batches

Must be of type Seed or Plant (units always recorded in pieces).

Only active batches are included; archived batches are excluded.

Includes batches with zero stock, ensuring complete traceability.

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list. | The reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifier of each batch of seeds or clones. | Unique identifier of the plant or article batch | Uses the Plant Batch Name (for plant batches) or Batch ID (for article batches). |

THC content (3) | Select from the drop-down list the range corresponding to the THC content of the seeds or clones (e.g., THC <0.30% / THC ≥0.30%). | Classification based on THC percentage. | Derived from the related cultivar:

|

Batch start date (4) | Record the batch start date in dd-mm-yyyy format. It must correspond to the date the batch entered the company/system, regardless of the reporting month. This is the creation date. This date does not change, even if the batch is reported across several months | Date the batch was created or entered the system. |

|

Initial stock (5) | Record the weight of seeds, in grams, in stock at the start of the month. | Stock at the beginning of the reporting month. | Reflects the total quantity in stock on the 1st day of the month. |

Seeds or clones imported (6) | Total seeds or clones in the batch that were imported and entered stock for the first time. | Seeds or clones received from external sources. | Populated from Goods In entries and manual stock adjustments (where applicable). |

Other sources of origin (7) | Total seeds or clones in the batch that entered stock in the month that were not from importation. If this column is filled, where applicable, indicate the origin in the Comments/Observations (13) column | New clones generated internally. |

|

Seeds or clones used in cultivation (8) | Record the quantity, in grams, of seeds or clones used for cultivation. | Quantity transferred into cultivation. |

|

Seeds or clones used for testing/analysis (9) | Record the quantity, in grams, of seeds or clones used for laboratory analyses/testing. If a sample is destroyed after testing, do not record it as “Destroyed.” | Quantity taken for laboratory analysis. |

|

Seeds or clones relocated internally within the company (10) | Seeds or clones transferred between the company’s own facilities, if the company has more than one authorized cultivation site. | Transfers between company sites. | Not currently available in Cannavigia. Always “0”. |

Seeds or clones destroyed (11) | Seeds or clones that were discarded, lost, damaged, contaminated, or intentionally destroyed, either directly by the company or by third parties contracted for that purpose. | Quantity destroyed, lost, or discarded. | Derived from “Record Waste” actions in the system. |

Final stock (12) | Record the total weight of seeds or clones in the batch remaining in stock at the end of the month being reported. | Remaining stock at the end of the month. | Calculated based on all recorded inflows and outflows during the month. |

Comments observation (13) | Use this column to add any information you consider relevant to understanding the record, about the batch or the operations that occurred this month. If more than one comment, separate them with a semicolon. | Additional traceability information. | Automatically includes batch origins or sources (e.g. “Source: PB-Mother01”). |

Notes & Limitations

Goods out of clones and seeds are not listed in this table

Internal relocation between sites is not yet supported.

Article batches are only included if they originate from Goods In.

Clones and seeds are counted in units (pcs) and not grams (g)

Sold clones are shown in Table 2: Harvest.

All Plant batches that are created from article batches that were manually created are excluded from the report

Table 2: Harvest

The Harvest Report focuses on all cultivation activities related to plant growth, harvesting, and motherplant management within the selected reporting period.

It consolidates data from cultivation batches and harvest batches, ensuring full traceability of plant movements, growth stages, and yields.

The report includes the following data sources:

Plant Batches

All active cultivation batches during the reporting month are included, regardless of their growth phase (Immature, Vegetative, Flowering, or Harvest).

All motherplant batches are also included, independent of their current phase.

Information on harvested weight and plant count is drawn from all harvest batches related to each plant batch.

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list. | Reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifying code for each batch. Each batch that had any movement in the month must have its own row. | Unique identifier for each plant or motherplant batch. | Derived from the Plant Batch Name in Cannavigia. Every batch with activity in the month appears once. |

THC content (3) | Select from the drop-down list the range corresponding to the THC content of the seeds or clones (e.g., THC <0.30% / THC ≥0.30%). | Classification of the cultivar based on THC percentage. | Based on the related cultivar:• THC ≥ 0.30% → Narcotic = true• THC ≤ 0.30% → Narcotic = false |

Start date cultivation (4) | Record the date on which mother plants were generated or new clones were propagated. | Date when cultivation or propagation began. | Start date of the immature phase for cultivation batches, or creation date for motherplants. |

Utilized area (5) | The total area (in square meters, m²) occupied by the batch of plants. This area may or may not coincide with the authorized area. | Area occupied by the batch. | Calculated from the main assigned area’s width × length. The related area must have a defined size. If multiple batches share one area, area name appears in Comments. |

Current batch stage (6) | Select the stage—Propagation, Vegetative, Flowering, or Harvest—of the batch in the month when the movement was recorded. | Growth phase of the batch at month-end. |

|

Amount of mother plants (7) | Record the number of mother plants If the batch corresponds to the creation of new mother plants obtained from seeds or by converting clones, indicate the number of mother plants generated. If the batch corresponds to clones produced from existing mother plants, indicate how many mother plants were used to generate the clones recorded in field (8). If the batch corresponds to imported/purchased clones or cuttings, without internal use or creation of mother plants, fill this field with 0 (zero). | Count of active mother plants in the batch. | Only for motherplant batches: plant count at month-end. Non-mother batches = 0. Includes new or converted motherplants during the month. |

Number of new plants for cultivation (8) | Indicate the total number of young plants (e.g., clones, cuttings, seedlings) introduced into this batch and intended for cultivation during the reporting month. This value must include both plants propagated internally (from mother plants or | Number of plants added to the batch during the month. |

|

Number of harvested plants (9) | Record the number of plants harvested, total quantity (U). | Total plants harvested. | Non-mother batches only. Calculated from related harvest batches created in the month. |

Total mass harvested plants (g) (10) | Record the weight of the plants harvested from the batch. | Wet weight of harvested plants. | Sum of wet weights from related harvest batches, minus log losses with reason “Corrections.” |

Number of destroyed mother plants (11) | Record the total number of mother plants destroyed, including those at the end of their life cycle. | Mother plants destroyed during the month. | Motherplant batches only. Derived from “Destroy Plants” actions. |

Total mass of destroyed mother plants (g) (12) | The total mass (in g) of the mother plants recorded in column (11) this month. | Weight of destroyed mother plants. | Recorded waste weight for destroyed whole motherplants. Excludes other waste. |

Number of destroyed plants (13) | Record the number of plants destroyed or lost during cultivation, except for mother plants already marked in column (11). In this same column, record all plant parts eliminated during the vegetative and flowering phases. Plant waste generated after harvest must be recorded separately in the “Cultivation – Post-harvest” sheet/tab. | Destroyed plants during cultivation (non-mother). | Non-mother batches only. Based on destruction entries in the month. |

Total mass of destroyed plants (14) | The total mass (in g) of the dead/lost/destroyed plants recorded in column (13) for the respective batch and month. | Weight of destroyed plants (non-mother). | Derived from waste records for whole plants only. Excludes other waste. |

Total number of plants designated for processing (15) | Indicate the number of fresh plants transferred for post-harvest processing.Record the number of fresh, undried plants that were sold or transferred to third parties. Transfers to third parties include situations where the company contracts trimming, drying, and stabilization services from another company licensed for that practice. | Plants transferred for post-harvest processing. | Equals Number of Harvested Plants. Used to indicate transfer for trimming/drying/stabilization. |

Total number of plants sold or transferred to external entities (16) | Record the number of fresh, undried plants that were sold or transferred to third parties. Transfers to third parties include situations where the company contracts trimming, drying, and stabilization services from another company licensed for that practice. The company receiving the fresh plant for post-harvest processes (trimming, drying, and stabilization) must complete the “Cultivation – Stock & Sales” sheet to record plant inflows and outflows and “Cultivation – Post-harvest” to record weights at each stage. The company sending the fresh plant for post-harvest processes must also record the finished product back into its stock when it is returned. | Plants sold or transferred to local third parties. | Derived from Goods Out records where Contact Country = Organization Country. |

Total plant mass sold or transferred to third parties (17) | Record the total mass/weight (in grams) of the plants (or plant material, such as fresh flower) that were sold directly or transferred to other companies (third parties) for post-harvest services (such as trimming, drying, and stabilization). | Total wet mass of plants sold or transferred. | Currently not tracked automatically – missing flow for post-harvest service transfers. |

Total number of exported plants (18) | Record the number of fresh, undried plants exported. | Plants exported to other countries. | Derived from Goods Out records where Contact Country ≠ Organization Country. |

Exported plant mass (19) | Record the total mass/weight (in grams) of the plants exported, as indicated in (17) | Wet weight of exported plants. | Not currently tracked automatically – a flow to send material for external processing is not modeled in Cannavigia. |

Notes & Limitations

Internal relocation of plants between facilities is not currently supported.

Post-harvest mass transfers (columns 17 & 19) are not yet fully automated.

Only whole-plant waste is included in destruction data.

Localization: Batch stages are displayed in the user’s language.

On production batches the Number of Mother plants of the parent batch is not taken into account. This column only reflects the amount of plants in active mother plant batches.

Split plant batches will show as 0 new plants for cultivation, as they are already accounted for in the source batch.

All Plant batches that are created from article batches that were manually created are excluded from the report

Table 3: Post Harvest

The Post-Harvest Report provides a detailed overview of all activities and material movements that occur after harvesting, covering the key post-harvest processes of trimming, drying, and stabilization (curing).

It is designed to ensure traceability and accurate stock control throughout the post-harvest phase, capturing both processed yields and material losses.

The report includes the following data sources:

Harvest Batches

All active harvest batches (batches that have actions recorded) during the reporting month are included.

The report tracks mass changes and waste generation resulting from trimming, drying, and stabilization processes.

This includes all weigh-ins, log losses, and waste records linked to each harvest batch.

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list. | Reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifier of each batch of seeds. Each batch that had any movement in the month must have its own row. | Unique identifier for each harvest batch. | Derived from the Harvest Batch ID in Cannavigia. Each batch with any activity in the month appears once. |

Harvest date (3) | Indicate the harvest date. | Date the harvest took place. | Taken from the user-entered Harvest Date field. This value can be edited manually in Cannavigia. |

Number of harvested plants (4) | Record the total number of harvested plants (U) in the batch being processed. This column is not applicable to companies receiving fresh plant for post-harvest processes (trimming, drying, stabilization); they must instead complete the following column (3). | Total number of plants harvested in the batch. | Calculated from the number of plants assigned to the harvest batch when it was created. |

Wet weight of plants (5) | Record the total weight of fresh plant material (g), after harvest but before any primary/coarse trimming. | Total fresh weight immediately after harvest, before trimming. | Computed as: total wet weight weighed in minus any log loss entries in the wet phase with reason Corrections.Represents the initial unprocessed wet mass. |

Wet weight before trimming (6) | Record the total weight of plant material (g) before starting trimming (cutting/pruning). | Fresh weight before trimming begins. | Identical to Wet Weight of Plants.Reflects the total wet weight added to the harvest batch. |

Weight after trimming (7) | Record the total weight of plant material (g) after completing trimming (cutting/pruning). | Weight of material after trimming (cutting/pruning). | Sum of all wet-phase actions: + weigh-ins (wet weight) − log losses (Corrections, Theft, Processing, Drying) − processing task waste. Represents wet weight remaining after trimming or similar wet processing steps. |

Weight before drying (8) | Record the total weight of plant material (g) before starting the drying process. | Weight of plant material before drying. | Identical to Weight After Trimming.Shows wet weight minus all reductions from processing or log losses. |

Weight after drying (9) | Record the total weight of plant material (g) after completing the drying process. | Weight of plant material after first drying process. | Sum of all weigh-ins (dry weight) recorded after the first drying processing or log losses are subtracted from this total. |

Weight before stabilization (10) | Record the total weight of plant material (g) before starting the stabilization (curing) process. | Weight before the stabilization/curing process. | Shows the initial weight of the final drying process (if multiple drying cycles exist).Excludes the first drying that transitions the batch from wet to dry. |

Weight after stabilization (11) | Record the total weight of plant material (g) after completing the stabilization (curing) process. | Final dry weight after stabilization/curing. | Sum of all weigh-ins (dry weight) recorded after the final drying of the batch. |

Total weight of plant waste (12) | Record the total weight of vegetal waste (g) generated during trimming, drying and/or stabilization processes, per batch | Total vegetal waste generated during trimming, drying, or stabilization. | Includes all waste and log loss entries (reason: Processing) in both wet and dry phases.Excludes losses recorded with reason Drying. |

Comments/Observations (13) | Use this column to add any information you consider relevant to understanding the record, about the batch or the operations that occurred this month. If more than one comment, separate them with a semicolon. | Additional remarks relevant to the batch or post-harvest operations. | Free-text field for contextual information (optional). Separate multiple comments with semicolons. |

Notes & Limitations

Multiple Drying Cycles:

Cannavigia supports several drying processes. Only the first drying marks the transition from wet to dry; later dryings are included in stabilization.Missing Weight Flows:

No automated tracking currently exists for product sent to external post-harvest service providers (e.g., outsourced trimming or curing). These transfers must be verified manually.Waste Classification:

Only processing waste and log losses (reason: Processing) are included in the waste totals. Other loss types (e.g., Drying) are excluded.Editable Harvest Date:

The Harvest Date field is user-editable in the system, which can affect which month the batch appears in. Users should validate this date before final reporting.Received Material:

Companies performing only post-harvest activities (receiving material) do not report harvested plant counts here — only processing and weight data are shown. Not automatically reported from Cannavigia.

Table 4: Stock and Sales

The Stock & Sales Report provides a comprehensive overview of all cannabis stock movements — including inflows, outflows, and balances — within the selected reporting period.

It is designed to ensure traceability, inventory accuracy, and a consistent mass balance across all product batches.

The report includes the following data sources:

Article Batches

Includes all article batches that have an associated cultivar.

Excludes batches of type Plant or Seed.

Only includes batches that originate from Goods In or from Harvest Batches.

Data is recorded only in grams (g).

Displays only batches that had at least one transaction during the reporting month (e.g., inflow, outflow, or destruction).

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list. | Reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifier of each batch of seeds. Each batch that had any movement in the month must have its own row. | Unique identifier for each cannabis product article batch. | Derived from the Article Batch Code in Cannavigia. Includes all batches with any transactions in the reporting month. |

Product type (3) | Select from the drop-down list the situation that applies (Examples: fresh/undried flower, dried flower). | Describes the form or classification of the product (e.g., fresh flower, dried flower). | Taken directly from the Article Name associated with the batch. |

Inventory at start of month (4) | Record the total quantity (in grams) of cannabis in stock on the first day of the month. This value must correspond to the “Stock at the end of the month (g)” of the previous record for the same batch and product type. | Total cannabis stock at the beginning of the reporting month. | Calculated as the total of all transactions before the 1st day of the month. This value must match the “Inventory at End of Month” from the previous report. |

Harvest yield (5) | Indicate the quantity (in grams) of cannabis harvested for the batch. This field refers only to cannabis originating directly from the harvest of your own operation. Do not include cannabis acquired or transferred from other sources. | Cannabis quantity produced internally from harvests. | Populated when the batch originates from a harvest batch. Includes manual stock adjustments that increase batch size. |

Incoming material from external sources (6) | Indicate the quantity (in grams) of cannabis—whether fresh or dried flower—acquired from another licensed company or received from another licensed company exclusively for post-harvest services (trimming, drying, stabilization), without transfer of ownership. | Cannabis quantity received from other licensed entities (domestic or international), without transfer of ownership. | Populated when Source = Goods In. Uses the Arrival Date as the reference date. Includes manual stock adjustments (both additions and removals). |

Transaction date (7) | Indicate the date of the first destination movement of the cannabis (i.e., the date on which the stock left for tests, transfers, sales, or destruction). Use the DD/MM/YYYY format | Date of the first outbound movement from the batch. | Determined from the Packaged Date (Package harvest batch) or Arrival Date (goods in), depending on the transaction type. |

Test / analyses (8) | Record the quantity (in grams) of cannabis from this batch that was sent for quality tests, laboratory analyses, or quality control, whether internal or external. Include here only the cannabis used for this purpose that does not return to marketable stock. | Quantity of cannabis used for laboratory analysis or quality control. | Recorded when samples are taken from the batch. Represents product used exclusively for testing and not returning to saleable stock. |

Retention sample (9) | Record the retention sample. When the sample is destroyed, record the value under Losses/Destroyed. | Quantity reserved for long-term retention or reference. | Currently not recorded in Cannavigia — always returns 0. |

Transferred internally within the same licensed entity (10) | Indicate the quantity (in grams) of cannabis from this batch that was moved to another facility or site operating under the same license of your entity, without a sale. | Cannabis quantity moved between facilities under the same license. | Currently not supported in Cannavigia — always returns 0. |

Sales or transfers in the domestic market (11) | Record the quantity (in grams) of cannabis from this batch that was sold or transferred to other entities (companies, distributors, etc.) within Portugal. The company that purchased or received the goods must record it in stock. | Quantity of cannabis sold or transferred within the domestic market. | Derived from Goods Out transactions where Contact Country = Organization Country. |

International sales - export (12) | Record the quantity (in grams) of cannabis from this batch that was sold and exported to customers or entities in foreign markets | Quantity of cannabis exported to other countries. | Derived from Goods Out transactions where Contact Country ≠ Organization Country. |

Loss and destruction (13) | Indicate the quantity of cannabis (in g) that was deliberately destroyed, for example due to contamination, non-conformity, excess stock, or other reasons, excluding normal process waste (such as stems, non-commercial leaves, etc.). | Cannabis destroyed due to contamination, non-conformity, or voluntary disposal. | Populated through Record Waste actions. Excludes normal process waste (e.g., stems, leaves, etc.). |

Inventory at the end of the month (14) | Record the final stock of cannabis (in g) for the batch at the end of the reporting month. This field is crucial for mass balance and inventory reconciliation. Make sure the calculation is correct. | Final stock quantity for the reporting month. | Calculated based on all transactions up to the last day of the month. Used for month-end stock reconciliation and mass balance. |

Comments Observations (15) | Use this column to add any information you consider relevant to understanding the record, about the batch or the operations that occurred this month. If more than one comment, separate them with a semicolon. | Additional remarks or context about the batch or operations. | Optional free-text field. Use semicolons to separate multiple comments. |

Limitations

Scope of Batches:

The report only includes article batches that:Have an associated cultivar

Are not of type Plant or Seed

Originate from Goods In or Harvest Batches

Have transactions during the month

Retention and Internal Transfers:

Columns for Retention Sample and Transferred Internally currently return 0 — these flows are not yet implemented in Cannavigia.Manual Stock Adjustments:

Manual additions or removals directly affect Harvest Yield or Incoming Material, and should be reviewed for accuracy.Editable Transaction Dates:

Dates derived from packaging or arrival entries may be modified in the system. Verify that transaction dates correctly fall within the reporting month.External Post-Harvest Services:

Incoming and outgoing material linked to post-harvest service contracts (e.g., trimming, drying) requires manual reconciliation if ownership does not change.

Table 5: Raw Materials

The Raw Materials Report provides a detailed overview of all inflows, outflows, and stock levels of cannabis raw materials within the selected reporting period.

It ensures complete traceability of all raw material movements — from production and procurement to usage and destruction — supporting accurate inventory management and compliance.

The report includes the following data sources:

Article Batches

Includes all article batches of the type “Raw Material.”

Each batch must have an associated cultivar.

Raw materials can originate from Harvest, Goods In, or Manufacturing sources.

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list | Reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifier of each batch of seeds. Each batch that had any movement in the month must have its own row. | Unique identifier for each batch of raw material. | Derived from the Article Batch ID. Each batch with activity in the reporting month appears. |

Raw material type (3) | Select from the drop-down list the option that applies (Examples: dried flower, extract, etc.). | Specifies the category of the raw material (e.g., dried flower, crude extract, resin, oil). | Taken from the Article Name field. Since there is no separate “type” attribute matching Infarmeds type requirement, the article name is used as a descriptive indicator. |

THC content (4) | Select the corresponding THC content of the raw material. | Classification of the raw material based on THC concentration. | Based on the related cultivar setting: Narcotic = true → THC > 0.3%• Narcotic = false → THC ≤ 0.3% |

Initial stock (5) | Enter the total quantity of the selected raw material in stock at the start of the reporting month. This value must correspond to the “Final Stock” of the previous record for the same type of raw material and batch. | Total quantity of raw material in stock at the beginning of the month. | Calculated from all transactions before the 1st day of the month. |

Harvested internally (6) | Indicate the quantity of cannabis raw material obtained directly from your own cultivation operation. If there is no own harvest, leave blank or fill “0.” | Quantity of raw material derived directly from in-house cultivation. | Populated when weight is added from a harvest batch as the source. |

Domestically sourced material (7) | Record the quantity of cannabis raw material acquired from other producers or suppliers within Portugal. | Quantity of raw material acquired from suppliers within Portugal. | Populated from Goods In transactions where Contact Country = Organization Country. |

Imported material (8) | Enter the quantity of cannabis raw material imported from other countries during the month. | Quantity of raw material imported from foreign suppliers. | Populated from Goods In transactions where Contact Country ≠ Organization Country. |

Used in manufacturing (9) | Indicate the quantity of cannabis raw material used in manufacturing or transformation processes (e.g., to produce extracts, pharmaceutical products, etc.). | Quantity of raw material consumed in production or transformation processes. | Calculated from all “Add Material to Production” actions performed during the month. |

Test/analyses (10) | Record the quantity of cannabis raw material allocated to quality tests, laboratory analyses, or quality control, whether internal or external. | Quantity of raw material used for internal or external laboratory analysis. | Derived from “Take Sample” actions performed on article batches. |

Material loss and destruction (11) | Enter the quantity of cannabis raw material destroyed during the month, indicating the reason (e.g., out of specification, contaminated, surplus, etc.) in “Comments/Observations.” | Quantity of raw material destroyed or discarded during the month. | Populated from “Record Waste” actions that remove material from stock. Reasons for destruction can be added under Comments / Observations. |

Stock final (12) | Record the total quantity of cannabis raw material in stock at the end of the reporting month | Total quantity of raw material in stock at the end of the month. | Calculated from all transactions up to the last day of the month. Used for end-of-month inventory reconciliation. |

Comments / Observations (13) | Use this column to add any information you consider relevant to understanding the record, about the batch or the operations that occurred this month. If more than one comment, separate them with a semicolon. | Additional notes or contextual information. | Automatically populated with the articles unit of measure in the format “Unit of measure: <unit>” |

Limitations

Scope of Data:

The report only includes article batches that:Are of type “Raw Material”

Have an associated cultivar

Originate from Harvest, Goods In, or Manufacturing sources

Article Type Classification:

Because Cannavigia does not have a matching “type” attribute for articles required by Infarmed, the article name (e.g., Flower, Oil, Extract) is used to represent the material type. Consistent naming conventions are important for clarity.Manufacturing Usage Tracking:

Quantities recorded as “Used in Manufacturing” depend on correctly using the Add Material to Production action. If material is consumed outside this workflow, it may not appear in the report.No Unit Conversion:

All entries are measured in grams (g). Cannavigia does not automatically convert other units (e.g., liters, milliliters) into grams for this report.Imported vs. Domestic Sources:

Determined exclusively by the Contact Country of the supplier. Users should ensure contact records are correctly configured to reflect origin.

Table 6: Final Products

The Final Products Report provides an overview of all final product batches produced, sold, or destroyed during the reporting month.

The report includes the following data sources:

Article Batches

Includes all article batches with the type “Final Product.”

Each article must have an associated cultivar.

Batches may originate from Goods In, Harvest, or Production sources.

Column | Regulatory Reference | Description | How It’s Calculated / Populated |

|---|---|---|---|

Month (1) | Select the month from the drop-down list. | Reporting period. | Automatically set to the selected reporting month. |

Lote (2) | Record the unique identifier of each batch of seeds. Each batch that had any movement in the month must have its own row. | Unique identifier for each final product batch. | Derived from the Article Batch ID. Includes all batches with any transaction during the month. |

Quantitiy used in production (3) | Record the total quantity in grams (g) or in the appropriate unit of measure (e.g., ml for liquids) of the raw material or intermediate product that was used to produce the final product described on this line. | Total amount of raw or intermediate material used to produce the final product. | Calculated from all “+ actions” in the transaction log within the month. |

Type of final product (4) | Select from the drop-down list the type of final product obtained. If the type is not on the list, contact the Directorate. | Specifies the product type (e.g., oil, capsule, extract, edible). | Taken from the Article Name in Cannavigia. |

THC content (5) | Select the corresponding THC content of the final product | Indicates whether the final product is considered narcotic or non-narcotic. | Based on the related cultivar: Narcotic = true → THC > 0.3%• Narcotic = false → THC ≤ 0.3% |

Total product output (6) | Record the total quantity in grams (g) or in the appropriate unit of measure (e.g., ml for liquids; units for capsules/tablets—specify the unit clearly) of the final product obtained after the manufacturing process. If the unit is not grams, clearly indicate the unit in the Comments/Observations column. | Total amount of final product obtained after manufacturing. | Calculated from all “+ actions” in the transaction log within the month. Units other than grams should be noted in Comments / Observations. |

Tests/analyses (7) | Indicate the quantity in grams (g) (or in the unit of measure of the final product) that was taken from production for quality tests, laboratory analyses, or quality control, whether internal or external. | Quantity of final product used for laboratory or quality testing. | Derived from Sample Weight entries associated with the final product batch. Represents material taken out for testing purposes. |

Retention sample (8) | Record the retention sample. When the sample is destroyed, record the value under Losses/Destroyed. | Quantity retained as a long-term reference sample. | Currently not implemented in Cannavigia – always returns 0. |

Domestic market sales (9) | Record the quantity in grams (g) or in the appropriate unit of measure of the final product that was sold and distributed in the Portuguese market | Quantity of final product sold or distributed within Portugal. | Populated from Goods Out transactions where: Goods Out Date is within the reporting month, and Contact Country = Organization Country. |

International sale - Export (10) | Indicate the quantity in grams (g) or in the appropriate unit of measure of the final product that was exported and distributed to markets outside Portugal | Quantity of final product exported to other countries. | Populated from Goods Out transactions where Goods Out Date is within the reporting month, and Contact Country ≠ Organization Country. |

Losses destroyed (11) | Enter the quantity in grams (g) or in the appropriate unit of measure of the final product that was destroyed during the month (losses inherent to the manufacturing process, material intentionally destroyed, or due to serious problems). | Quantity of final product intentionally destroyed or lost during production or storage. | Populated from Record Waste actions where Waste Date is within the month. Includes process losses, damaged goods, and destruction events. |

Stock final (12) | Record the total quantity in grams (g) or in the appropriate unit of measure of the final product in stock at the end of the reporting month. | Total quantity of final product in stock at the end of the month. | Calculated from all transactions recorded up to and including the last day of the month. Used for end-of-month inventory and reconciliation. |

Comments / Observations (13) | Use this column to add any information you consider relevant to understanding the record, about the batch or the operations that occurred this month. If more than one comment, separate them with a semicolon. | Additional remarks or context about the product, batch, or movement. | Will be automatically populated with a comment containing “Unit of measurement: <article unit>” |

Limitations

Scope of Data:

The report only includes article batches that:Have type “Final Product”

Have an associated cultivar

Originate from Goods In, Harvest, or Manufacturing

Have at least one transaction within the selected month

Retention Samples:

The Retention Sample field is currently non-functional in Cannavigia and always reports 0. Any destruction of retained material must be manually recorded under Losses / Destroyed.Unit Management:

Products may be recorded in grams (g), milliliters (ml), or units (pcs). The system does not convert between these automatically — the correct unit are automatically specified manually in Comments / Observations.THC Classification:

The “THC Content” field relies on the associated cultivar configuration. If the cultivar’s Narcotic status is not set correctly, THC classification in the report is inaccurate.Transaction Dependencies:

The report relies on transaction log data. Missing or incorrect process entries (e.g., unrecorded production steps) will cause incomplete reporting.Sales and Export Dates:

Outgoing product date are determined by the Goods Out Date. Ensure these dates are accurate to avoid discrepancies in monthly summaries.